The Latest Trend in Oil Condition Monitoring

ERASPEC OIL is a portable stand-alone infrared analyzer for high-speed lubricant oil analysis and condition monitoring in full compliance with ASTM, DIN and JOAP methods. Its patented interferometer design delivers laboratory-grade results directly on site. ERASPEC OIL measures contaminants, degradation products, additive depletion as well as calculated properties like TAN, TBN, and viscosity within seconds.

Lubricant Analysis with IR Spectroscopy

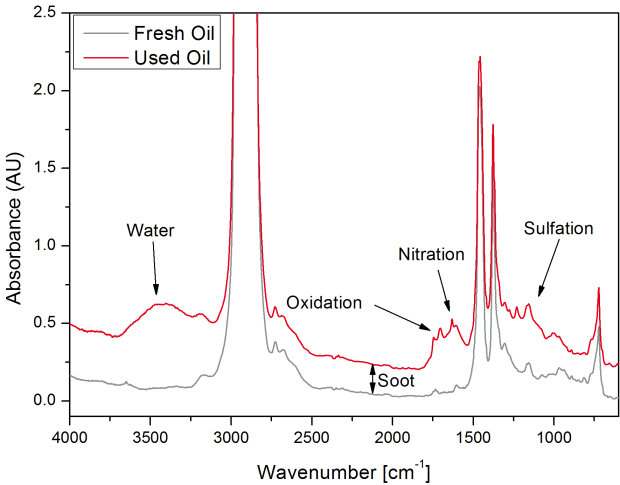

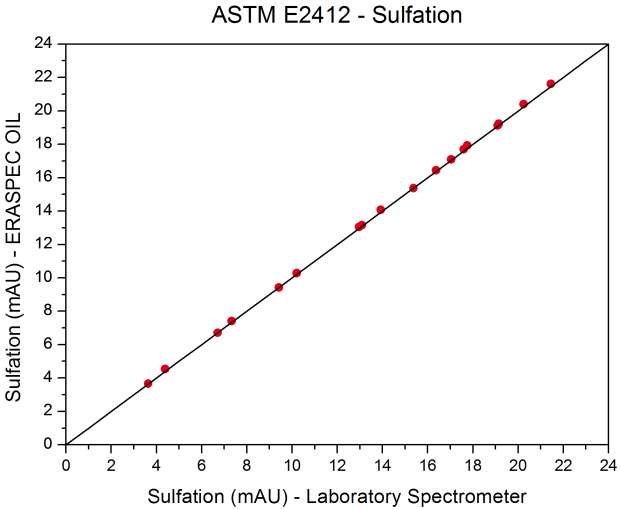

Lubricant oils exhibit various chemical changes during their life time. This starts by simple changes such a fuel dilution of the fuel used or the uptake of soot (ASTM E2412) from the combustion. Numerous chemical reactions with combustion products lead to oxidation (ASTM D7414), nitration (ASTM D7624) or sulfation (ASTM D7415) of the lubricant and can be summarized as degradation products. To enable cycle times known from modern lubricants a wide variety of additives are added. These additives are used up during operation.

All of them can be readily monitored by IR spectroscopy.

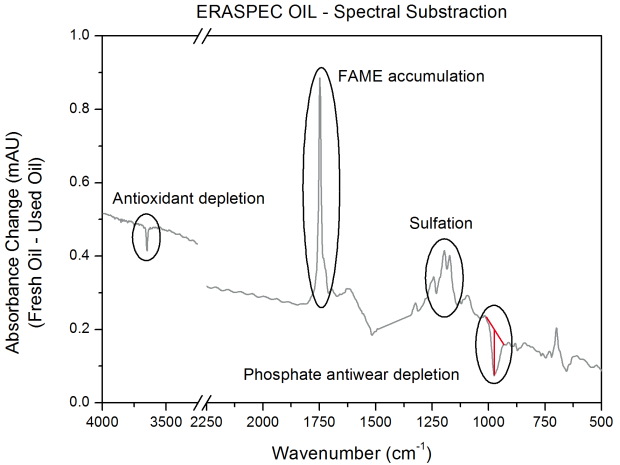

Direct Trending and Spectral Subtraction

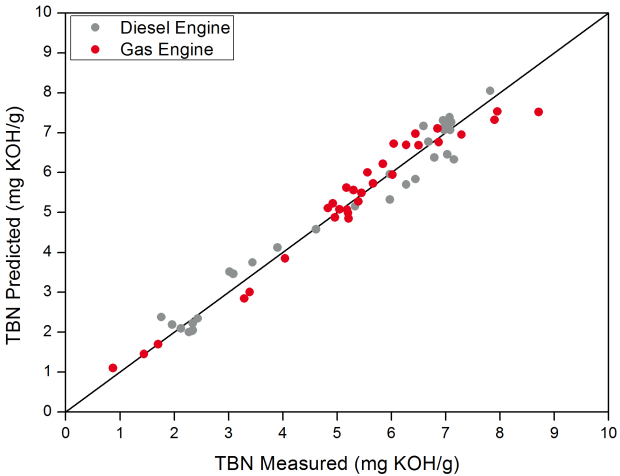

When performing an used oil analysis with ERASPEC OIL one of two methods can be chosen. With "Direct Trending" the lubricant properties are directly calculated from the recorded absorbance. With "Spectral Subtraction" the fresh oil is used (and stored) as reference before the measurement and is subtracted from the measured in-service oil. Generally speaking “Spectral Subtraction” gives better results as only the changes to the oil during operation are analyzed. Knowing the spectrum of the fresh oil allows the measurement of the remaining anti oxidants in percentage for example. Complex parameters such as TAN & TBN or viscosity are calculated by chemometrical models based on databases containing used oil spectra of known values.

Expandable Databases

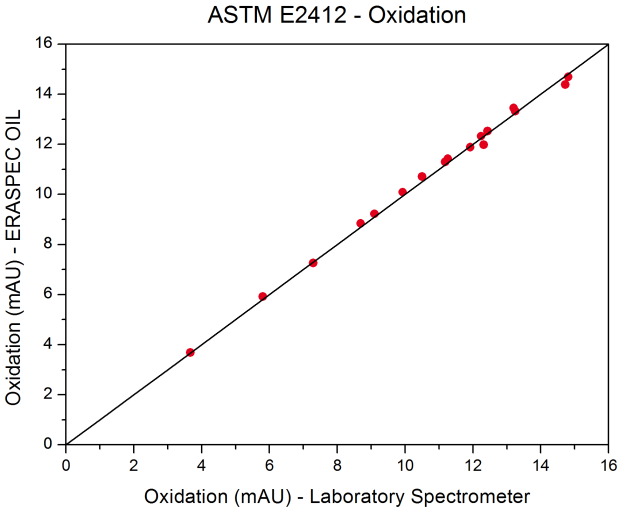

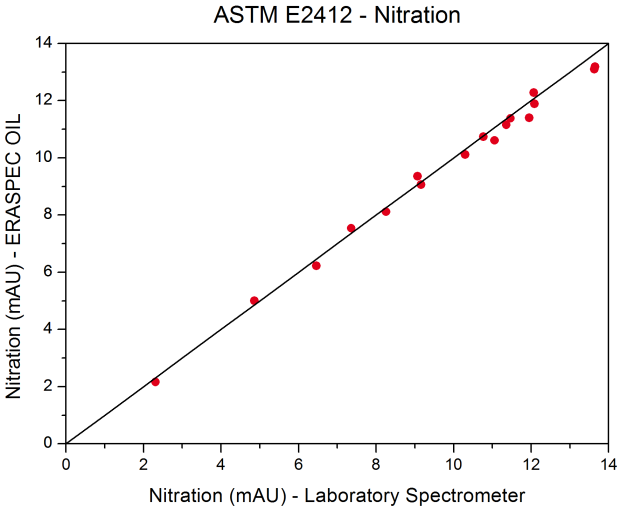

ERASPEC OIL is equipped with different databases for oil property calculations as different engines use up the oil differently. Using the wrong database will lead to incorrect results of the calculated properties. Choosing the correct database, however, allows various parameters to be predicted with high precision. Beside the already included libraries, new customized libraries can be easily added, thus improving the results of your oil analysis even further. Using customized libraries gives ERASPEC OIL the ability to learn completely new parameters that are not covered by the factory libraries.

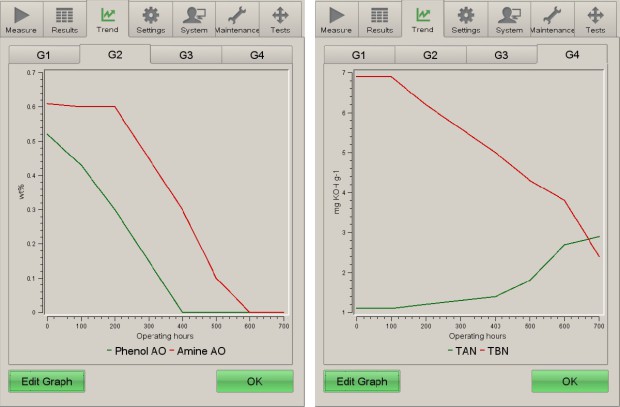

On-screen Trending Graphs

ERASPEC OIL offers the possibility to plot the measurement results of the used oil analysis directly on the large color touchscreen. This allows to track the temporal changes of parameters of interest. ERASPEC OIL can plot the values of the driven distance of an engine or the operating ours of a gas turbine for example. All relevant information, such as trending ID, fresh oil spectrum and libraries needed, are pre-configured on the instrument. After selecting the trending ID a measurement is run and the trending graphs are display directly afterwards. That way, for example, a sudden rise in oxidation or a major drop in base reserve will be noted at first glance directly on-site.

Lab-grade Performance

Eralytic's patented rugged and light-weight FTIR spectrometer design allows measurements giving results as previously known from laboratory systems only. With its ligth-weight instrument design ERASPEC OIL can easily be brought on-site. For the operation at remote locations ERASPEC OIL can also be operated by a vehicle battery. There is no need to send in samples for analysis anymore.

Using ERASPEC OIL you can bring you laboratory oil analysis directly to spot where the analysis results are need.

Automatic Reference Measurement

In IR spectroscopy always two measurements are needed: A reference measurement of the background and a sample measurement. Often the reference measurement is performed by filling the measurement cell with a solvent because a measurement of the empty cell is not favorable due to optical interferences.

ERASPEC OIL uses a special reference cell to automate the background measurement process. Whenever a new reference is needed the instrument can perform this measurement automatically so that ERASPEC OIL is always ready for the next sample measurement when needed.

Measurement Procedure

To perform spectral analysis with the ERASPEC OIL analyzer can be done in 4 sample steps:

- Select the oil type and enter sample ID, as well as operator name

- Select the method (Direct Trending, Spectral Subtraction or a Trend) and follow the instructions on the display

- Put your sample or fresh oil next to the fuel analyzer and insert the inlet tube

- Press the RUN button

The measurement steps are visualized on the display, showing the deflection of the moving mirror of the interferometer. When the measurement is completed the results are displayed and can be printed or added to a library with a single click. When the sample belongs to a trend measurement, this trend of all corresponding samples can be displayed, too.

| Available Test Methods |

ASTM E2412, ASTM D7412, ASTM D7414, ASTM D7415, ASTM D7418, ASTM D7624, ASTM D2668 JOAP, DIN 51452, DIN 51453 |

| Correlation to... |

ASTM D445, ASTM D664, ASTM D2270, ASTM D2896, and ASTM D4739 |

| Spectrometer Type |

Patented mid-FTIR spectrometer |

| Measurement Cell |

100 µm path length |

| Calibration |

Factory calibrated with a matrix of international lubricants |

| Spectral Libraries |

Easy expandable libraries to adjust measurements to target applications and user-defined parameters |

| Measurement Principles |

Direct trending: calculation of results without the need to record a fresh opil spectrum |

| Measuring Time |

60 - 120 seconds depending on the viscosity of the sample |

| Sample Introduction |

Directly from the sample container by an integrated pump |

| Sample Viscosity |

0 - 2,000 cSt at 20°C |

| Sample Volume |

10 mL |

| Cleaning |

Automatic rinsing with next sample or solvent |

| Display |

Industry proven 8.4" color touchscreen |

| Languages |

English, German, French, Spanish, Russian, Chinese |

| Interfaces |

Built-in PC with Ethernet, USB and RS232 interfaces |

| Remote Control |

Remote service capability via Ethernet interface |

| PC Software |

ERASOFT RCS - remote control Windows® software for multi-instrument remote control, convenient data transfer, viewing spectra and result analysis |

| Result Database |

Approx. 3,000 detailed test reports and spectra stored in the internal memory |

| Alarm Tracking |

All alarm messages are stored in the database together with the results |

| Auto Sampler |

Optional 10-position auto-sampler - directly attached |

| Operating Conditions |

Temperature range 5°C to 45°C |

| Power Requirements |

Auto switching 85-264 V AC, 47-63 Hz, max. 150 W (multi-voltage power supply) |

| Dimensions / Weight |

29 x 35 x 34 cm (11.4 x 13.8 x 13.4 in) / 9.7 kg (21.4 lb) |

There are no reviews yet

Recently viewed products

eralytics ERACOUNT XS, The Fastest ISO 4406 Particle Counter

| SKU | PSC-47-15374 |

| MPN | ECT10 |

eralytics ERAVISC X, 2-in-1 Viscosity & Density with Lab Precision

| SKU | PSC-47-14370 |

| MPN | EVX10 |

eralytics ERAOIL, RDE-OES Spectrometer for Elemental Analysis

| SKU | PSC-47-15135 |

| MPN | EOL01 |