The Safe Side of Flash Point Testing

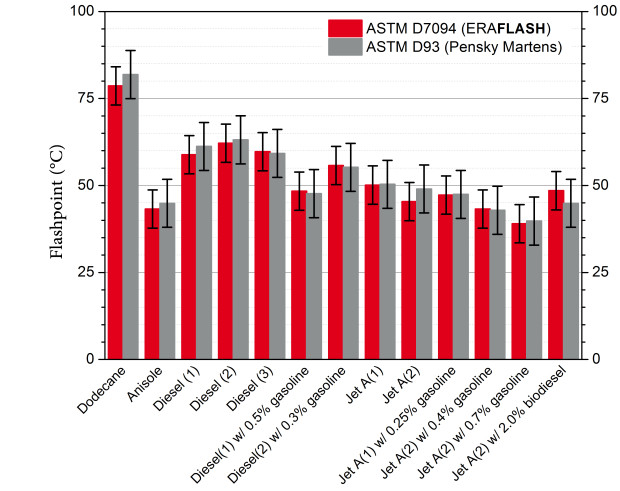

The flash point tester ERAFLASH measures in full compliance with the continuously closed cup flash point testing methods ASTM D6450, ASTM D7094 as well as the European equivalent IP620. ASTM D7094 shows no statistical bias to the former ASTM D93 Pensky Martens method. The sample volume is only 2 ml. During measurements an electric arc ignites the sample vapor and the analyzer determines the flash point by the pressure change inside the closed cup. Flash point testing never was safer and easier.

ASTM D7094 and ASTM D6450

ASTM D6450 was the first Continuously Closed Cup Flash Point (CCCFP) and uses 1 ml sample volume only. To further improve the correlation to the well-established ASTM D93 Pensky Martens method a modified successor method was developed.

ASTM D7094 (Modified CCCFP) uses 2 ml of sample volume and a different heating rate than ASTM D6450 with the effect that it shows no statistical bias to ASTM D93 (Pensky Martens). This was proven by an ASTM round robin test in 2004.

In addition this round robin showed, that the actual repeatability and reproducibility of ASTM D7094 is up to 50% better than the values stated in ASTM D93.

Fuel Specifications Testing

In December 2013 ASTM D7094 was accepted as the first official alternative for fuel specification testing as it gives equivalent results to ASTM D93 and even outperforms it in terms of reproducibility:

- Fuel oil (ASTM D396)

- Diesel fuel (ASTM D975)

- Gas turbine fuel oil (ASTM D2880)

- Kerosene (ASTM D3699)

- Diesel Fuel, Biodiesel Blend (ASTM D7467)

Unmatched Range Meets High Performance

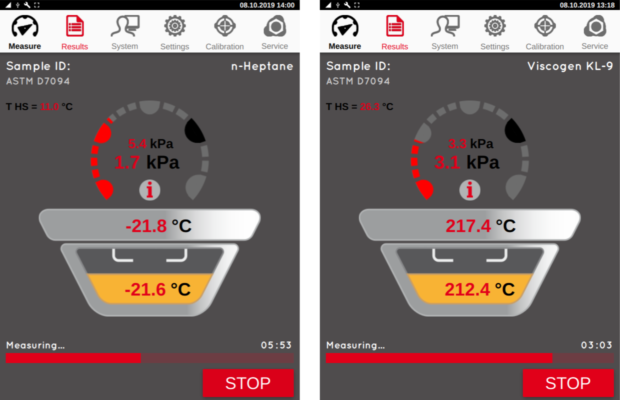

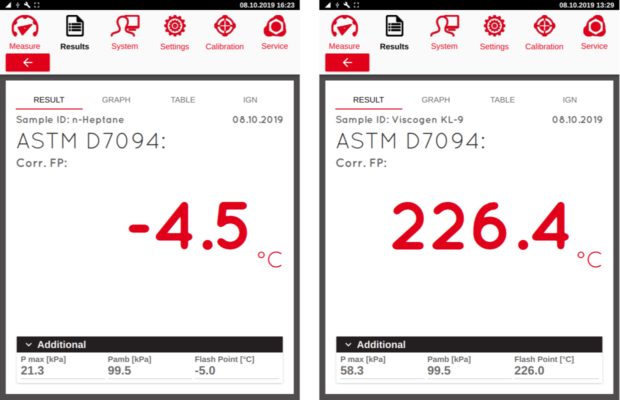

Eralytics’ patented PBT – Peltier Boost Technology™ allows flash point testing below 0°C (32°F) and above 200°C (392°F) with a single instrument. This technology separates the Peltier elements during the heat up from the oven to prevent any damage to them at high temperatures. Additionally the Peltier elements can be used during cool down at temperatures that would normally harm them. Thus, the turnaround time is significantly shortened. On top PBT makes ERAFLASH the only flash point tester on the market covering a temperature range of -25°C (-13°F) to 420°C (788°F).

High Sample Throughput with Minimum Maintenance

The innovative PBT – Peltier Boost Technology™ allows previously unmatched heating and cooling rates, which in combination with the low sample volume decreased the turnaround time significantly for flash point testing. Additionally the CPT – Contamination Prevention Technology™, which is a combination of advanced electrode protection and self-cleaning procedures, reduces the time required for cleaning and maintenance to an absolute minimum, increasing the sample throughput even further.

Measurement Procedure

Just four easy steps are required for a safe flash point testing at maximum precision:

- Enter sample ID and operator name

- Select the measurement standard and add additional parameters (e.g. expected flash point)

- Fill the sample cup with sample, place the sample cup inside the measurement chamber, and close the door

- Press the RUN button

The instrument now visualizes the measurement procedure on the screen showing the sample and oven temperature as well as pressure gauge displaying the pressure increase after ignition. After the measurement the flash point temperature is corrected for the atmospheric pressure and rounded to the next 0.5 °C. The result will be saved in the corresponding result file.

Characteristics of the flash point testing can be seen in the Combustion Graphics™. This makes ERAFLASH the ideal solution for R&D as well as quality control.

| Available Test Methods |

ASTM D6450, ASTM D7094, IP620, SH/T 0768 |

| Pre-Programmed Correlation Methods to... |

Pensky Martens Closed Cup: ASTM D93, EN ISO 2719, DIN 51758, IP34, JIS K2265 |

| Fuel Specifications (ASTM D7094) |

ASTM D396, ASTM D975, ASTM D2880, ASTM D3699, ASTM D7467 |

| Speed Tests |

Fast screening test programs for unknown samples |

| PBT - Peltier Boost Technology™ |

High speed heating & cooling |

| CPT - Contamination Prevention Technology™ |

Advanced electrode protection and self-cleaning ignition system to minimize cleaning and maintenance |

| Combustion Graphics™ |

Display of combustion characteristics for contamination analysis |

| QuickCal™ |

In-situ calibration with eralytics unique calibration cups without the need of dismantling the instrument |

| Fuel Dilution Program |

Automatic fuel dilution measurement for the analysis of used engine oils |

| QC Mode |

Built-in quality control mode including on-screen QC charts |

| Temperature Range |

0°C to 200°C (32°F to 390°F) stand alone. No external cooling is required. |

| Temperature Stability |

0.1°C (0.2°F) |

| Sample Throughput |

Up to 12 samples per hour |

| Sample Volume |

1 mL (ASTM D6450), 2 mL (ASTM D7094, IP620) |

| Sample Cups |

Nickel plated aluminium, stainless steel cups available upon request |

| Display |

Industry proven 8.4" multilingual color touchscreen |

| Languages |

English, German, French, Spanish, Russian, Chinese |

| Interfaces |

Built-in PC with Ethernet, USB and RS232 interfaces |

| Remote Control |

Remote service capability via Ethernet interface |

| PC Software |

ERASOFT RCS - remote control Windows® software for multi-instrument remote control, convenient data transfer and result analysis |

| Result Database |

Over 100,000 detailed test reports stored in internal memory |

| Alarm Tracking |

All alarm messages are stored in the database together with the results |

| Operating Conditions |

Temperature range 10°C to 40°C |

| Power Requirements |

Auto-switching 85-264 V AC, 47-63 Hz, max. 150 W (multi-voltage power supply) |

| Dimensions / Weight |

29 x 35 x 34 cm (11.4 x 13.8 x 13.4 in) / 9.7 kg (21.4 lb) |

There are no reviews yet

Recently viewed products

eralytics ERAFLASH, Flash Point Tester

| SKU | PSC-47-03840 |

| MPN | EF10 |