FeDDI provides a complete automated method, which replaces the inherently difficult visual quantification referenced in NACE TM0172 and ASTM D665 while using a four-step automated vision algorithm and classification process to eliminate user bias and provide repeatable results.

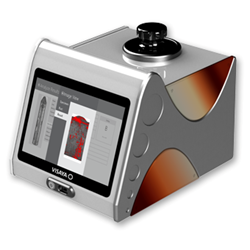

Iron/Rust Digital Detection Imaging

Corrosion on steel pipelines and tanks can lead to destructive leaks that can cost millions to fi x and cause irreversible environmental damage. As a result, industries spend billions each year to slow down the natural process of corrosion. The National Association of Corrosion Engineers (NACE) indicates that small amounts of water, air, and polar compounds are some of the biggest threats to petroleum pipeline corrosion.

As such, NACE carefully monitors levels of corrosion by testing the interior of pipes for these substances adverse effects. The NACE system of testing as well ASTM and other standardized methods are dependent upon a manual rating process in which the operator must quantify small percentages of corrosion by visually inspecting a test specimen that has been bathed in a mixture of test fuel and distilled water. This procedure is highly susceptible to operator error. In addition, due to differences in visual acuity, results are not repeatable.

FeDDI, from VISAYA Inc., was designed to solve the difficulties of rating in NACE TM0172 and D665 specimens accurately. It uses a four-step automated vision algorithm and classification process to eliminate user bias and provide repeatable results. After scanning a specimen’s entire surface area, corrosion coverage is quantified. FeDDI provides a complete automated method, which replaces the inherently difficult visual quantification referenced in NACE TM0172 and ASTM D665. FeDDI has the capability of displaying both unfiltered images and filtered images after subtracting marks, spots, sagging and any other anomalies present in the untested specimen.

| Applicable Test Methods |

ASTM D665, ASTM D7548, IP 135, ISO 7120, JIS K2510, NACE TM-01-72 |

| Corrosion Detection Range |

Corrosion Coverage 0.01 mm to 100% |

| Display Units |

Corrosion %, Specimen Size & Rating |

| Detection Method |

Patent Pending CMOS Digital Detection |

| Precision |

± 0.01% of Raw Reading |

| Dimension |

± 0.085mm of Height & Width |

| Pixel Size |

0.035mm per Pixel |

| Optical Design |

Patent Pending Optical Arrangement |

| Light Source |

LED, 7,000K |

| Measuring Time |

2.5 minutes |

| Calibration |

Vision Calibration with Standard |

| Display |

10.1" Projective Capacitance Touch (Multi Touch) |

| Interface |

Ethernet x2, USB 3.0 x1, USB 2.0 x4, HDMI, VGA, USB Printer, USB Mouse and Keyboard |

| Memory / Storage |

64 GB SSD Storage |

| Temperature Range |

10° to 35°C |

| Humidity |

Up to 85% Non Condensing |

| Power |

Auto-switching 90 ~ 264VAC, 47 ~ 63Hz, 280 Watt Power Supply |

| Space Requirements |

80 mm (3") on Sides and Back |

| Dimension |

350 x 300 x 270 mm (14 x 12 x 11") |

| Gross Dimensions & Weight |

Weight 10 kg (22 lbs) |

There are no reviews yet

Recently viewed products

FeDDI – Iron/Rust Digital Detection Imaging

| SKU | PSC-47-06412 |

| MPN | AYA-10-88590 |