Sample Precision

From start to finish, the Welker CP-2 Constant Pressure Cylinder is the container for the safe collection and transport of accurate samples for laboratory analysis.

Repeatable Results

Pre-charging the CP-2 with an inert gas or pipeline gas allows the sample to be collected at pipeline pressure. No pressure drop during sample collection protects against phase change and ensures sample integrity.

In the laboratory, connect a gas supply with pressure equal to pipeline pressure to the pre-charge side of the cylinder. As the sample is injected into the analyzer, full pressure is maintained in the cylinder, thus ensuring a representative sample and repeatable results for accurate billing.

Proven Safety

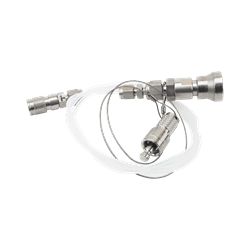

Both ends of the CP-2 come equipped with valves, gauges, and pressure relieving devices. These safety measures allow the operator to control and monitor the cylinder pressure and prevent the cylinder from overpressurizing. The tie bolts provide a secondary level of safety; in the event of overpressurization, the tie bolts will stretch to allow pressure to relieve, preventing fragmentation of the cylinder.

Homogeneous Samples

Achieve a uniform mix for accurate sample analysis using one of Welker’s mixers. The internal Gravity Mixer™, ideal for products that stratify, ensures even distribution of the sample within the cylinder. Suitable for high viscosity products and products that stratify, the mixing action of the vortex mixer creates spiral movement in the sample, which pulls the product toward the middle of the cylinder and ensures a proper mix.

Portable

The CP-2 is designed as a DOT 3E cylinder and is transportable with special permit DOT-SP 7657. The high pressure CP-2 is designed as a DOT 3A cylinder and is transportable with special permit DOT-SP 11054.

For added convenience, transport the CP-2 using a lockable Welker Carrying Case with carry handles and wheels. Cut to conform to your cylinder, the internal PrecisionFoam™ stabilizes and protects your investment during travel.

Superior Design

The internal floating piston serves three purposes:

- Volume Indication

- Contamination Prevention

- Environmental Protection

Volume Indication

As the cylinder fills with the sampled product, the piston moves, allowing product level to be easily monitored by referring to the graduated scale or volume indicator rod.

Contamination Prevention

As the cylinder is emptied, the piston wipes the cylinder walls clean and forces out any air and/or contaminants, preventing cross-contamination between samples.

Environmental Protection

Pre-charging the cylinder prior to sample collection pushes the piston to the product side, meaning there is no large volume to purge. The CP-2 eliminates the need for the fill and empty method and thus prevents large volumes of gas from being vented to the atmosphere.

| Materials of Construction |

316/316L Stainless Steel |

| Seal Material Options |

Viton® |

| Sample Inlet Connections |

1/4" FNPT |

| Sample Outlet Connections |

1/4" FNPT |

| Cylinder Volume Options |

50 cc |

| Cylinder Mixer Type |

Gravity Mixer™ |

| Cylinder Accessories |

Rupture Disc, Reliefs, Valves, and Gauges |

| Operating Pressure |

1800 psig MAOP @ -20 °F to 120 °F |

| Transport Approvals |

DOT-SP 7657 |

| Industry Standards |

Complies with API 8.1, API 14.1, ASTM D1265, ASTM D3700, ASTM D4057, GPA 2166, GPA 2174, ISO 3170, ISO 4257, and ISO 10715 |

There are no reviews yet

Recently viewed products

Welker CP-2GM Constant Pressure Cylinder (CPC), with Gravity Mixer

| MPN | CP-2GM |